Toys

LLDPE and HDPE have long played a major role in the toy plastic industry due to their cost-effectiveness, molding capabilities and ability to produce complex shapes. Rotomolded plastic is resilient to breaking, straining, and rough play from little hands, while blow-molded and injection molded toys enable a variety of products to come to life. At Shell Polymers, we aim to provide polymers that converters, brands and parents can count on for their plastic toys.

2025 industry trends shaping the future of plastic toys

The plastics industry is competitive and keeping pace with packaging industry trends is crucial for growth. In our Shell Polymers 2025 Trend Report, we’ll explore trends, threats and opportunities for converters, including a look at shifts that affect the toy plastic market.

Product summary

View blow molding product details

View blow molding product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers HDPE 46BG6HLU | 6.0 HL | 0.946 | View technical properties |

| Shell Polymers HDPE 48BG9HL | 9.0 HL | 0.948 | View technical properties |

| Shell Polymers HDPE 55B035 | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 55B035A | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 63B072 | 0.72 | 0.963 | View technical properties |

View injection molding product details

View injection molding product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers HDPE 48N5 | 5.0 | 0.948 | View technical properties |

| Shell Polymers HDPE 52N7 | 6.5 | 0.952 | View technical properties |

| Shell Polymers HDPE 52N10 | 10.0 | 0.952 | View technical properties |

| Shell Polymers HDPE 54N20 | 20.0 | 0.954 | View technical properties |

| Shell Polymers HDPE 65N8 | 8.2 | 0.965 | View technical properties |

View rotomolding product details

View rotomolding product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers LLDPE 35R5U | 5.2 | 0.935 | View technical properties |

| Shell Polymers LLDPE 35R7U | 7.0 | 0.935 | View technical properties |

| Shell Polymers LLDPE 39R4U | 3.5 | 0.939 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers HDPE | View technical properties |

| Shell Polymers LLDPE | View technical properties |

| Shell Polymers Polyethylene Wide Spec or Offspec | View technical properties |

Product 101

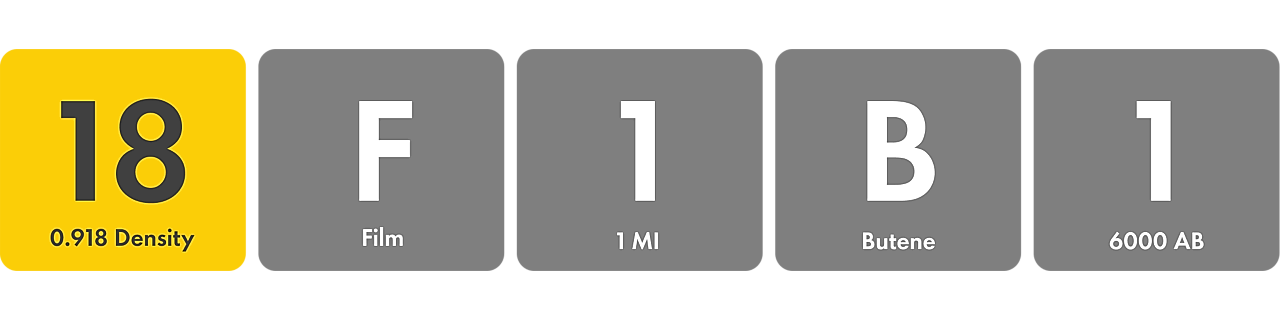

Understanding our grade slate system helps you know what toy plastic is best for your needs, from roto-molding playground equipment and structures to injection molding and blow-molding indoor plastic toys.

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Related conversion processes

Different conversion processes can take the same polymers and transform them into a wide variety of toy plastics—from rotomolded playground structures to blow-molded pails.

Blow molding

Blow molded HDPE is used to make hollow products such as industrial containers and drums, liquid containers and more.

Injection molding

Injection molded LLDPE and HDPE is used to make caps, bottle closures, toys and more.

Rotomolding

Rotomolded HDPE and LLDPE is used to make large products such as playgrounds, industrial containers and more.

Stay informed with Shell Polymers

Our monthly newsletter keeps plastic converters like you up to date with the latest on toy plastics, including insights on economic updates, material shortages, new regulations and other factors impacting rotomolding, blow molding, and injection molding operations. Sign up now to get the latest on plastic toys.

Expert insights on the toy plastics market

Four tips to prevent rotomolding defects

Minimize expensive rotomolding defects with these expert insights.

How to enhance your plastic injection molding operation in 3 steps

Learn how your choice of lubricant can impact production, equipment availability, and downtime.

How to prepare for LLDPE rotational molding operations

Learn three best practices when it comes to LLDPE rotomolding.