Polyethylene products

At Shell Polymers, we recognize that plastic converters like you need durable polyethylene resin, reliable supply and trusted support. That’s why our versatile high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE) are rigorously analyzed and tested for resistance to chemicals, melting point consistency and performance before arriving at converter plants. Beyond material performance and quality, we also recognize the need for a polyethylene supplier that you can trust—one that puts your interests first, listens to understand and helps turn your big ideas into market-ready solutions.

Polyethylene product families

Leveraging high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE) in applications makes durable products that that offer excellent resistance to chemicals, abrasion, extreme temperatures and more. When a part needs to be strong, flexible and produced efficiently, HDPE and LLDPE are go-to materials—offering the performance plastic converters like you can rely on across a wide range of applications.

HDPE resin

HDPE is a popular choice across a variety of industries because of its moisture and chemical resistance, impressive tensile strength and durability.

LLDPE resin

LLDPE is known for its flexibility and resistance—making it ideal for lightweight and durable films, bags and pouches.

Find the right resin for your business

Looking for polyethylene products with specific melt index and density values? Use our

Product Selector to see what grades best fit your needs.

Our commitment to quality and performance

Product quality is key to your business success. Period. That’s why every area of the Innovation Center at our Pennsylvania plant is specially designed to help ensure that the polyethylene resin you receive meets your standards. From monitoring molecular weight and melting point to evaluating resistance to chemicals and end-use performance, our labs are equipped to support a wide range of polyethylene applications—from injection molded parts to blow molded packaging and more.

Ensuring lot-to-lot consistency

The Analytical Laboratory helps us produce highly consistent product, providing data that gets our resin as close as possible to the center of the specification range and to ensure railcars are near that range as well. This attention to detail and precision helps us deliver dependable and quality products for our customers.

Reducing downtime

The equipment in our Application Hall has advanced features to help you better understand our resins’ performance and make correlations with your processing equipment—allowing for more efficient qualification in your production lines without having to shut down your own facilities. You can work with our team of experts to conduct trials and ensure our polyethylene works well with your equipment before committing time and effort to calibrations.

Uncovering insights via testing

The Application Testing Laboratory analyzes specimens made in the Application Hall to confirm product performance such as mechanical and optical properties. This helps ensure product quality for converters and minimizes production issues—while also giving us the data we need to help improve our resin over time.

Conducting in-depth studies

In the Material Testing and Inspection Laboratory, we conduct a wide range of in-depth studies that characterize the mechanical, processing and visual properties of a polymer. This helps us ensure more accurate information is available for converters on our polyethylene resins—so you can feel good about your purchase decision and ensure you’re equipped to address your unique business needs.

Delivering technical expertise

From analytical chemists to polymer scientists and technical experts, our Innovation Center is home to more than 50 industry experts who are excited to work with you. Whether you want to raise operational performance, solve complex challenges or troubleshoot any potential issues, our industry experts are here to help.

The building blocks of polyethylene reliability

The polyethylene you need when you need it

We recognize the importance of polyethylene resin to your business—and that’s why we’ve built reliability into our operations. Located within 700 miles of most North American polyethylene product buyers, our Pennsylvania facility offers multiple strategic transportation options, a weather-proofed plant design and more to keep your business moving forward.

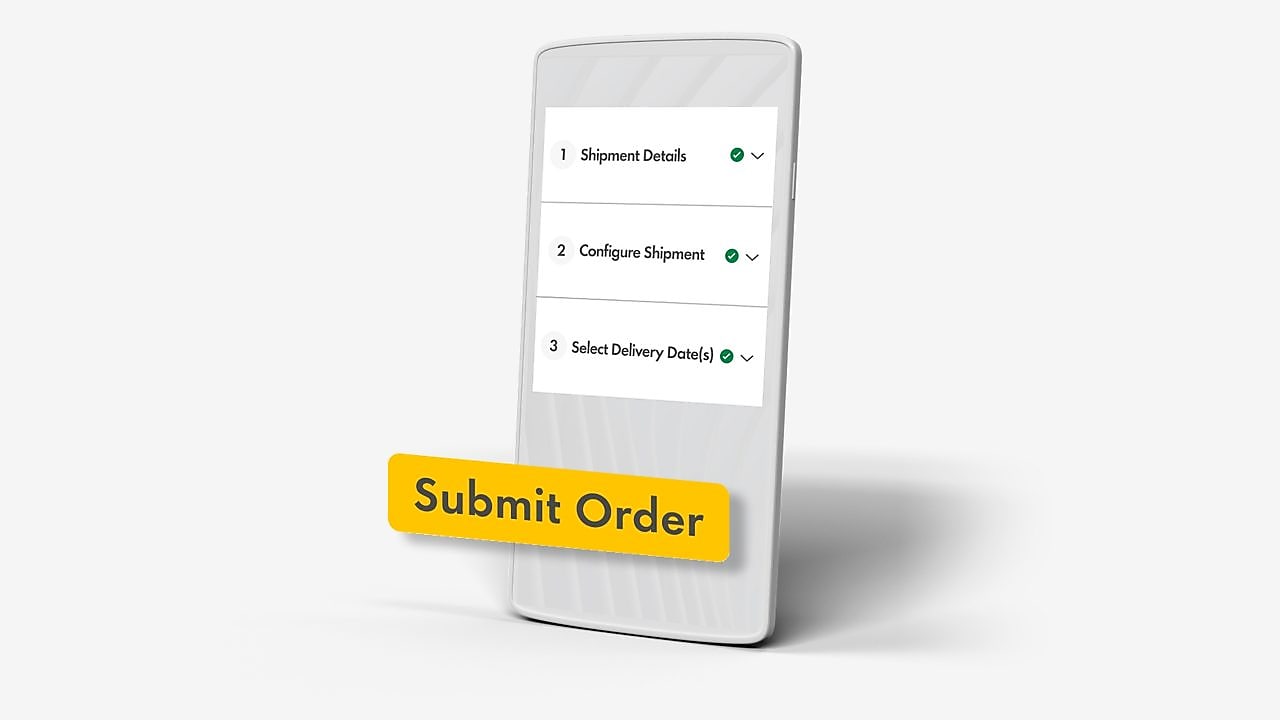

One holistic view into your business

When you become a Shell Polymers customer, you hold the key to efficiency with our Customer Hub. This platform helps you stay in tune with your business through shipment tracking, streamlined ordering, data-backed insights and more.

A supplier who really listens

We’re all about (Real)ationships at Shell Polymers. Nope, it’s no typo. A (Real)ationship is built on trust and transparency, bringing your big ideas to life and above all else—being real.

Stay informed with Shell Polymers

Our monthly newsletter is tailored for plastic converters working across a wide range of applications—from injection molded parts to blow molded packaging and film. Get the latest on polyethylene products, innovations in polyethylene resin, insights on evolving plastics types, and expert Shell Polymers tips to stay competitive and informed.

Have questions about our polyethylene products? Let’s connect.

Expert insights on polyethylene & market trends

Shell Polymers 2025 Trends Report

The polyethylene industry is always changing and keeping up with technological, regulatory and sustainability developments is key to long-term success. Staying ahead of these changes is critical for converters working with polyethylene products across diverse applications. Check out our report to learn the biggest trends for 2025.

The experienced team behind our polymer plant

From insightful industry experts and talented technicians to customer service specialists laser-focused on resolving your polyethylene issues, we couldn’t be prouder of our team of polymer pros.

How does the circular economy work?

Fighting plastic waste requires everyone to do their part, from consumers and brands to converters and suppliers. With advanced and mechanical recycling, we can help keep polyethylene moving and create a sustainable circular economy.