High density polyethylene (HDPE)

Known for its high tensile strength, stress crack resistance, and chemical resistant properties, high density polyethylene (HDPE) resins are ideal for converters seeking durable materials that perform reliably across injection molding, rotational molding and extrusion processes. As a trusted HDPE supplier, our Shell Polymers resins are designed to withstand high processing temperatures and demanding line conditions. Our commitment to quality and reliability sets us apart from other HDPE resin manufacturers—all so you can receive the necessary materials and product information to help optimize performance and throughput.

HDPE product specifications

Homopolymer safety data sheets (HDPE)

Get more detail on safe usage of our polyethylene homopolymer resins.

Hexene copolymer safety data sheets (LLDPE, HDPE)

Discover insights into safe usage of our hexene copolymer resins.

Find the right HDPE grade by density & melt index

Need grade slates of a certain melt index and density? Check out our Product Selector to see what solution best fits your needs.

Product summary

View HDPE product details for blow molding

View HDPE product details for blow molding

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers HDPE 46BG6HLU | 6.0 HL | 0.946 | View technical properties |

| Shell Polymers HDPE 48BG9HL | 9.0 HL | 0.948 | View technical properties |

| Shell Polymers HDPE 55B035 | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 55B035A | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 63B072 | 0.72 | 0.963 | View technical properties |

View HDPE product details for injection molding

View HDPE product details for injection molding

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers HDPE 48N5 | 5.0 | 0.948 | View technical properties |

| Shell Polymers HDPE 52N7 | 6.5 | 0.952 | View technical properties |

| Shell Polymers HDPE 52N10 | 10.0 | 0.952 | View technical properties |

| Shell Polymers HDPE 54N20 | 20.0 | 0.954 | View technical properties |

| Shell Polymers HDPE 65N8 | 8.2 | 0.965 | View technical properties |

View HDPE product details for pipe extrusion

View HDPE product details for pipe extrusion

| Product | Melt index | Density | Product details |

|---|---|---|---|

| Shell Polymers HDPE 48P9HL | 9.0 HL | 0.948 | View technical properties |

HDPE product 101

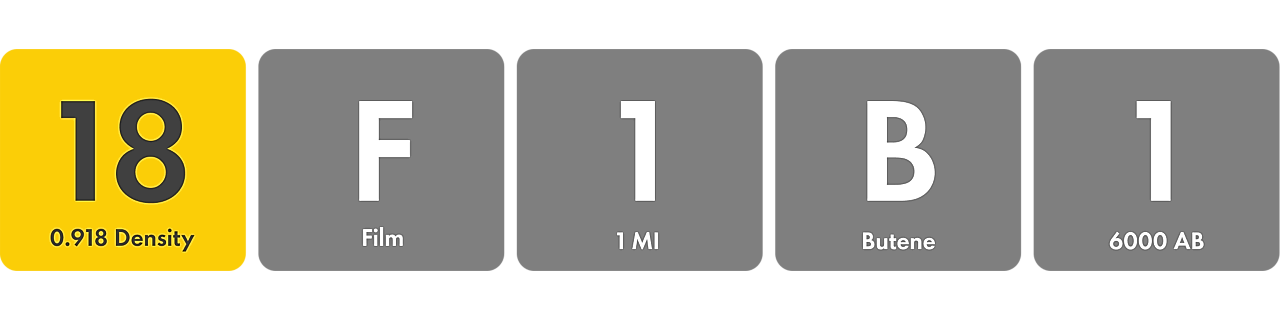

Understanding how we name our high density polyethylene (HDPE) grade slates will help you choose the right melt index and density for your needs. Explore the breakdown to confidently navigate our product details and access the product information that matters most.

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Related conversion processes

HDPE is used across a wide range of conversion processes, including injection molding, rotational molding, film extrusion, and more. With so many potential end-use applications, demand for HDPE has grown steadily for decades. As a trusted HDPE supplier, we can help converters like you tap into the full potential of HDPE.

Blow molding

Blow molded HDPE is used to make hollow products such as industrial containers and drums, liquid containers and more.

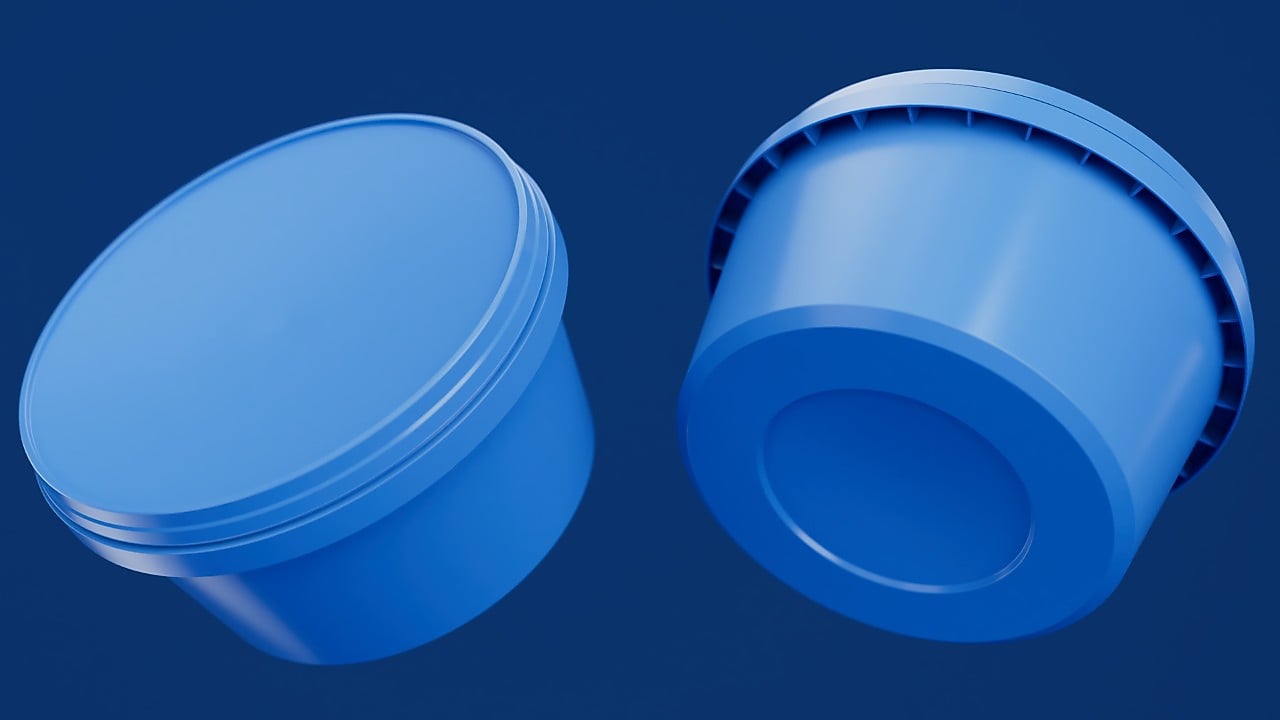

Injection molding

Injection molded HDPE is used to make caps, bottle closures, toys and more.

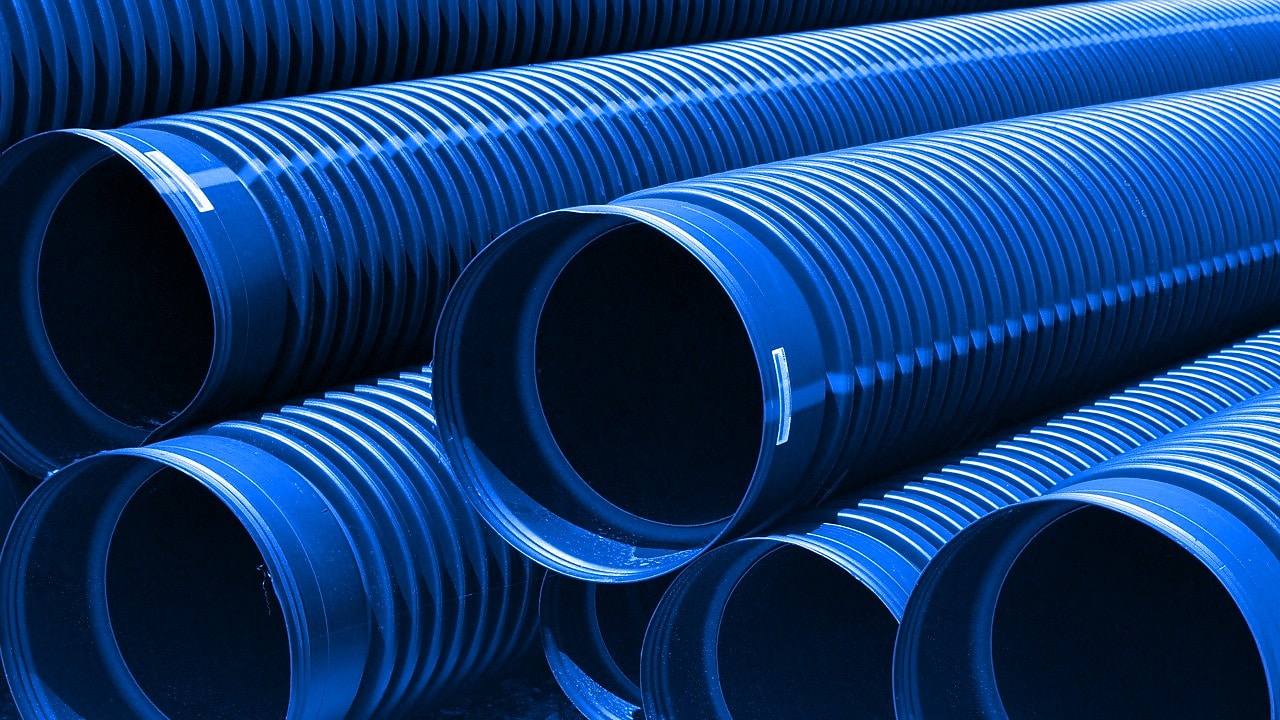

Pipe extrusion

Pipe extruded HDPE is used to make conduit, corrugated and pressure pipe.

Markets powered by HDPE

Shell Polymers has HDPE resin in a variety of melt indexes and densities engineered to meet the needs of plastic converters in diverse conversion processes. As a leading HDPE resin supplier, our materials support a wide range of end-use applications across these listed markets.

Agriculture

HDPE is used to create containers that can safely store agricultural products.

Industrial

Industrial containers and drums made from HDPE resin are more cost-effective and lightweight than many alternatives.

Automotive

Plastic is replacing metal for a growing number of car parts to support sustainability and electric vehicle efforts.

Outdoor living

A popular choice for outdoor applications, HDPE resin is built to withstand harsh elements.

Food packaging

HDPE resin enables economical and convenient packaging like bottles that are impact-resistant with high recycling capability.

Personal care

Cosmetic containers made from HDPE are more durable, making the trip down the assembly line to the consumer’s cabinet a smooth one.

Healthcare

The toughness and nonporous surfaces of HDPE resin make it perfect for protective shells encasing medical equipment.

Toys

The combination of durability and light weight makes HDPE resin ideal for products handled by young but energetic toddlers and kids.

Household

Durable and leak-resistant containers for household chemicals can be made with HDPE resin.

Utility infrastructure

The strength and weather resistance of HDPE resin make it a popular material for utilities.

Stay informed with Shell Polymers

Our monthly newsletter covers trends in high density polyethylene (HDPE) resin and other insights to help you optimize conversion processes like injection molding and rotational molding. Stay informed and make smarter material decisions with practical tips, technical guidance and industry updates tailored for plastic converters.

Expert guidance from a trusted HDPE supplier

Why the blow molded plastics market prefers HDPE

HDPE is incredibly versatile compared to other plastics and converters can use it to create an immensely diverse array of blow molded products across multiple applications.

Pipe extruders should look at HDPE resin as the future of utilities infrastructure

When it comes to underground pipes, high-density polyethylene is one of the most popular materials for the job—and for good reason.

How to enhance your plastic injection molding operation in 3 steps

Learn how your choice of lubricant can impact production, equipment availability, and downtime.