Find your product

Please use the below filters to explore our products and help you find the solution for your business.

Future considerations

Shell Polymers 18F1H

Process: Film extrusion

Melt Index: 1.0

Density: 0.918

Shell Polymers 18F1H1

Process: Film extrusion

Melt Index: 1.0

Density: 0.918

Shell Polymers 18F1H2

Process: Film extrusion

Melt Index: 1.0

Density: 0.918

Shell Polymers 18F1M

Process: Film extrusion

Melt Index: 1.0

Density: 0.918

Shell Polymers 18F1M6

Process: Film extrusion

Melt Index: 1.0

Density: 0.918

Shell Polymers 18F1M7

Process: Film extrusion

Melt Index: 1.0

Density: 0.918

Shell Polymers 18F1M8

Process: Film extrusion

Melt Index: 1.0

Density: 0.918

Shell Polymers 18F4M

Process: Film extrusion

Melt Index: 3.5

Density: 0.918

Shell Polymers 18F5M

Process: Film extrusion

Melt Index: 4.5

Density: 0.918

Shell Polymers 22F08B3

Process: Film extrusion

Melt Index: 0.8

Density: 0.922

Shell Polymers 23F1M

Process: Film extrusion

Melt Index: 1.0

Density: 0.923

Shell Polymers 24N20

Process: Injection molding

Melt Index: 20.0

Density: 0.924

Shell Polymers 25F08H

Process: Film extrusion

Melt Index: 0.8

Density: 0.925

Shell Polymers 25F08H1

Process: Film

Melt Index: 0.8

Density: 0.925

Shell Polymers 26N50

Process: Injection molding

Melt Index: 50.0

Density: 0.926

Shell Polymers 39P02U

Process: Pipe

Melt Index: 0.2

Density: 0.939

Shell Polymers 46B035

Process: Blow molding

Melt Index: 0.35

Density: 0.946

Shell Polymers 49P024

Process: Pipe

Melt Index: 0.24

Density: 0.949

Shell Polymers 49P9HL

Process: Pipe

Melt Index: 8.5

Density: 0.949

Shell Polymers 51P9HL

Process: Pipe

Melt Index: 9.0

Density: 0.951

Shell Polymers 54BG6HL

Process: Blow molding

Melt Index: 5.5

Density: 0.954

Interested to learn more?

From technical properties to applications and more, our team is happy to answer any questions you might have.

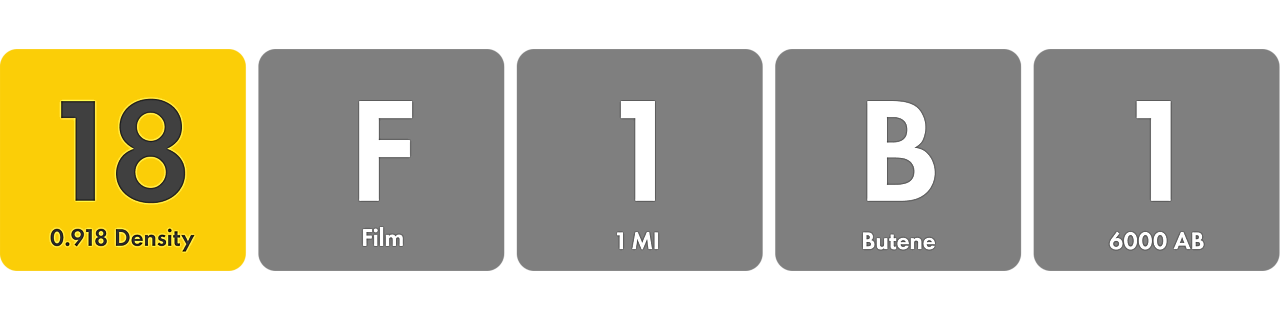

Product 101

Understanding how we name our grade slates will be key to choosing the right melt index and density you need. Whether you’re producing HDPE or LLDPE grades, selecting the right properties will help ensure optimal performance.

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density