Utility infrastructure

In the utilities industry, converters rely on materials that offer long-term strength, energy efficiency, and cost-effectiveness. That’s why many HDPE is a proven solution for modern utility infrastructure challenges. With its corrosion resistance, leak prevention, and durability, polyethylene pipe is ideal for safely transporting wastewater, chemicals, natural gas and compressed air across distribution networks and transmission lines. At Shell Polymers, we work with converters to help support the evolving needs of today’s utility companies—from new installations to aging power grid upgrades.

2025 industry trends shaping the future of utility infrastructure

The plastics industry is competitive and keeping pace with packaging industry trends is crucial for growth. In our Shell Polymers 2025 Trend Report, we’ll explore trends, threats and opportunities for converters, including a look at shifts that affect food manufacturing companies, grocery stores and brands producing processed food, soft drinks, and other packaged goods.

Product summary

View pipe extrusion product details

View pipe extrusion product details

| Product | Melt index | Density | Product details |

|---|---|---|---|

| Shell Polymers HDPE 48P9HL | 9.0 HL | 0.948 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers HDPE | View document |

| Shell Polymers Polyethylene Wide Spec or Offspec | View document |

Product 101

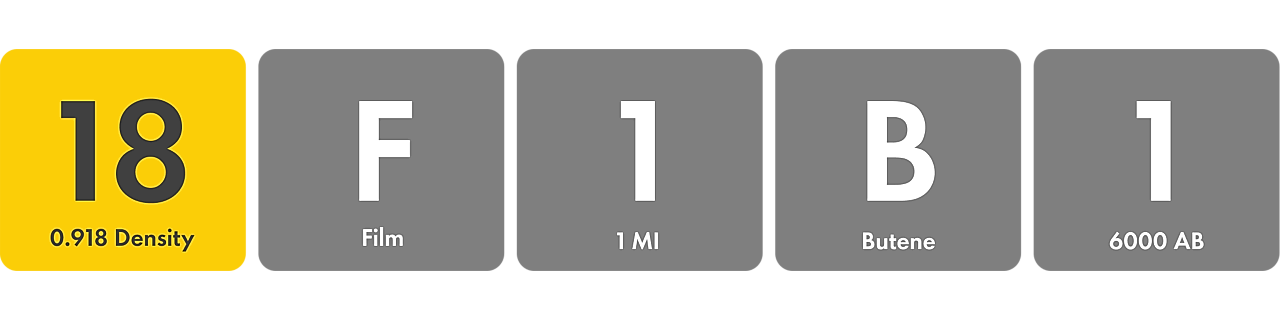

In utility infrastructure, selecting the right resin is critical to ensuring long-term strength, durability and compliance. Our grade naming system helps you quickly identify key resin properties such as melt index, density and processing behavior. Explore how our naming convention simplifies resin selection for pipe, conduit and other essential applications across the utilities industry.

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Related conversion process

Pipe extrusion is a critical conversion process for producing durable and corrosion-resistant pipe systems used across the utilities industry. It enables the creation of long-lasting materials that meet the performance demands of distribution networks, natural gas transport and other utility infrastructure applications.

Pipe extrusion

Pipe extruded HDPE is used to make conduit, corrugated and pressure pipe.

Have questions about utility infrastructure? Let's connect.

Our monthly newsletter keeps pipe extruders and utility companies informed with the latest on utility infrastructure trends, infrastructure investment updates and technical tips from Shell Polymers experts. From natural gas transport to distribution networks and energy efficiency, get the insights you need—delivered straight to your inbox.

Expert insights on utilities infrastructure

Breaking down salt and pepper mixing vs. precompounded

In some regions, resins are precompounded; in others, converters feed resin to the extruder with masterbatch. Some claim this “salt and pepper” mixing results in inferior quality—but is that actually true?

Pipe extruders should look at HDPE as the future of utilities infrastructure

Learn the benefits of using HDPE for underground pipe systems, from strength and durability to abrasion resistance and more.

Five things you need to know about HDPE pipe

HDPE pipe is a rapidly growing industry that’s attracting new investment. Learn why HDPE pipe is so useful and how working with the right polymer supplier can help you make the most of new opportunities.

Polymer Profile: Carl Baker, Senior Technical Service Engineer | Pipe

We’re proud of our team of polymer industry veterans and our lead expert on HDPE pipe is no exception. Learn Carl’s technical tips and recommendations for converters.