Healthcare

HDPE and LLDPE are driving innovation in healthcare packaging offering key advantages like enhanced hygiene, user comfort, and lower costs. Their compatibility with sterilized plastics and film extrusion makes them ideal for high-performance healthcare applications. At Shell Polymers, we provide resins designed to meet the demands of modern healthcare packaging—helping converters deliver safe and efficient solutions at scale.

2025 industry trends shaping the future of healthcare packaging

The plastics industry is competitive and keeping pace with industry trends is crucial for growth. In our Shell Polymers 2025 Trend Report, we’ll explore trends, threats and opportunities for converters. From material innovations to regulatory pressures, discover what’s next in healthcare packaging and how to stay ahead.

Product summary

View blow molding product details

View blow molding product details

| Product | Melt index | Density | Product details |

|---|---|---|---|

| Shell Polymers HDPE 46BG6HLU | 6.0 HL | 0.946 | View technical properties |

| Shell Polymers HDPE 48BG9HL | 9.0 HL | 0.948 | View technical properties |

| Shell Polymers HDPE 55B035 | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 55B035A | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 63B072 | 0.72 | 0.963 | View technical properties |

View film extrusion product details

View film extrusion product details

| Product | Melt index | Density | Product details |

|---|---|---|---|

| Shell Polymers LLDPE 18F1B | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F1B1 | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F1B2 | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F2B | 2.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 19F3B | 2.7 | 0.919 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers HDPE | View document |

| Shell Polymers LLDPE | View document |

| Shell Polymers Polyethylene Wide Spec or Offspec | View document |

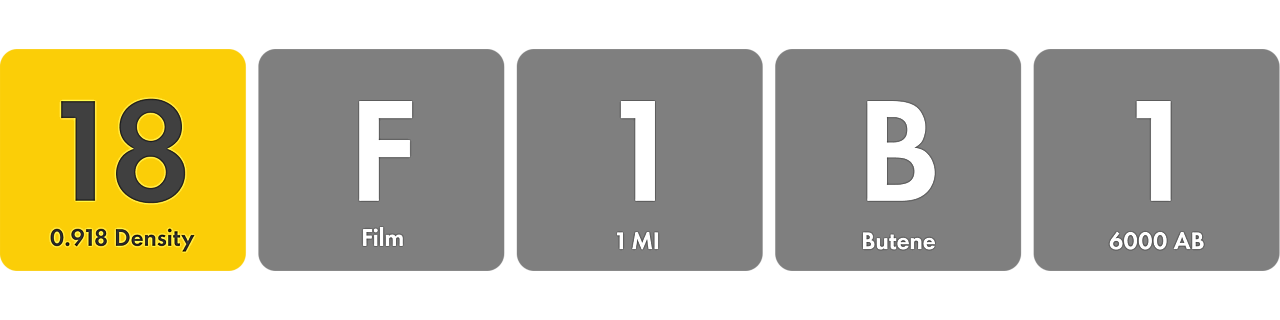

Product 101

In healthcare packaging, getting the resin right means getting performance, safety, and compliance right. That starts with understanding how we name our grade slates—a system built to help you quickly identify key resin properties like melt index and density. Read on to understand our naming convention and how you can choose the right polymer for healthcare applications.

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Related conversion processes

Learn how proven conversion processes like blow molding, and film extrusion help enable the production of precise and reliable healthcare packaging. These methods deliver the sanitation, hygiene, and performance medical applications demand, helping converters meet strict industry standards with confidence.

Blow molding

Blow molded HDPE is used to make hollow products such as industrial containers and drums, liquid containers and more.

Film extrusion

Film extruded LLDPE is used to make industrial and food packaging, stretch films and more.

Stay informed with Shell Polymers

Get the latest healthcare industry trends, technical guidance and resin insights delivered monthly to help you stay informed and competitive. Our experts break down what matters most in healthcare packaging, so you don’t miss a beat.

Expert insights on healthcare packaging

How polyethylene in medical applications help enhance the patient experience

Discover three benefits of leveraging polymers in medical applications.

Ensure a trouble-free film extrusion machine shutdown

Learn how a proper shutdown procedure can help maximize your productivity and margins.

High-quality resin can increase blow molding machine production

Improving production is always a top priority for converters and resin plays an important role in this. Learn how suppliers can help ensure resin meets a converter’s quality needs.