Automotive

Today’s vehicles rely on thousands of automotive plastic parts and that number is growing as manufacturers adopt automotive polymers like HDPE and LLDPE to improve part performance, reduce weight and support sustainability goals. At Shell Polymers, we provide high-quality resins that empower converters to produce durable, efficient plastic car parts—while supporting the adoption of new technologies and adaptation to fast-moving trends in automotive manufacturing.

2025 industry trends shaping the future of automotive plastics

The plastics industry is evolving rapidly—and staying ahead of emerging trends is key to maintaining a competitive edge. In the Shell Polymers 2025 Trend Report, we explore the top developments, risks, and growth opportunities impacting converters today, including those directly shaping the automotive manufacturing space.

Product summary

View blow molding product details

View blow molding product details

| Product | Melt index | Density | Product details |

|---|---|---|---|

| Shell Polymers HDPE 46BG6HLU | 6.0 HL | 0.946 | View technical properties |

| Shell Polymers HDPE 48BG9HL | 9.0 HL | 0.948 | View technical properties |

| Shell Polymers HDPE 55B035 | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 55B035A | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 63B072 | 0.72 | 0.963 | View technical properties |

View injection molding product details

View injection molding product details

| Product | Melt index | Density | Product details |

|---|---|---|---|

| Shell Polymers HDPE 48N5 | 5.0 | 0.948 | View technical properties |

| Shell Polymers HDPE 52N7 | 6.5 | 0.952 | View technical properties |

| Shell Polymers HDPE 52N10 | 10.0 | 0.952 | View technical properties |

| Shell Polymers HDPE 54N20 | 20.0 | 0.954 | View technical properties |

| Shell Polymers HDPE 65N8 | 8.2 | 0.965 | View technical properties |

View sheet extrusion product details

View sheet extrusion product details

| Product | Melt index | Density | Product details |

|---|---|---|---|

| Shell Polymers HDPE 55B035S | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 63B072S | 0.72 | 0.963 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers HDPE | View document |

| Shell Polymers Polyethylene Wide Spec or Offspec | View document |

Product 101

Understanding how we name our grade slates is key to selecting the right resin properties that impact everything from heat resistance and electrical insulation to fuel efficiency and part durability. Whether you're working with fiber reinforced materials or choosing among different types of plastic, our naming system helps you identify the best fit for your automotive manufacturing needs.

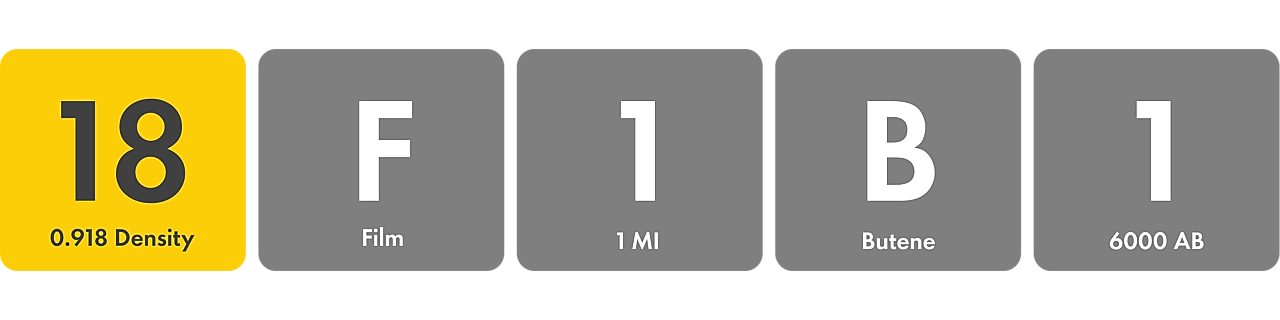

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Related conversion processes

Injection molding and blow molding are widely used in the production of automotive plastic parts, offering the strength, precision and moisture resistance needed for demanding vehicle environments from under-the-hood components to interior systems for electric vehicles. These conversion processes help meet the evolving performance and quality standards of today’s automotive industry.

Blow molding

Blow molded HDPE is used to make hollow products such as industrial containers and drums, liquid containers and more.

Injection molding

Injection molded LLDPE and HDPE is used to make caps, bottle closures, toys and more.

Stay informed with Shell Polymers

Join our monthly newsletter to stay informed on the latest automotive industry trends, technical tips, and automotive polymer insights, curated for plastic converters and delivered straight to your inbox by the Shell Polymers team.

Expert insights on automotive polymers

How plastic parts for the automotive industry are going to change moving forward

Check out how automotive manufacturing trends will impact the demand for plastic parts.

High-quality resin can increase blow molding machine production

See just how much of a difference high-quality HDPE resin makes to blow molding production.

How to enhance your plastic injection molding operation in 3 steps

Learn how your choice of lubricant can impact production, equipment availability, and downtime.