Agriculture

Plastics have reshaped farming—helping to power more efficient and resilient operations across a range of agricultural applications. From high and low tunnels to nursery pots, plastic mulch, corrugated pipe and irrigation infrastructure, modern ag plastics help support better yields, reduced labor and smarter resource use. At Shell Polymers, we are excited to help harness the power of these agricultural plastics to help plastic converters like you find success in this industry.

2025 industry trends shaping the future of agricultural plastics

The plastics industry is competitive and keeping pace with packaging industry trends is crucial for growth. In our Shell Polymers 2025 Trend Report, we’ll explore trends, threats and opportunities for converters, including a look at shifts that affect the agriculture market.

Product summary

View film extrusion product details

View film extrusion product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

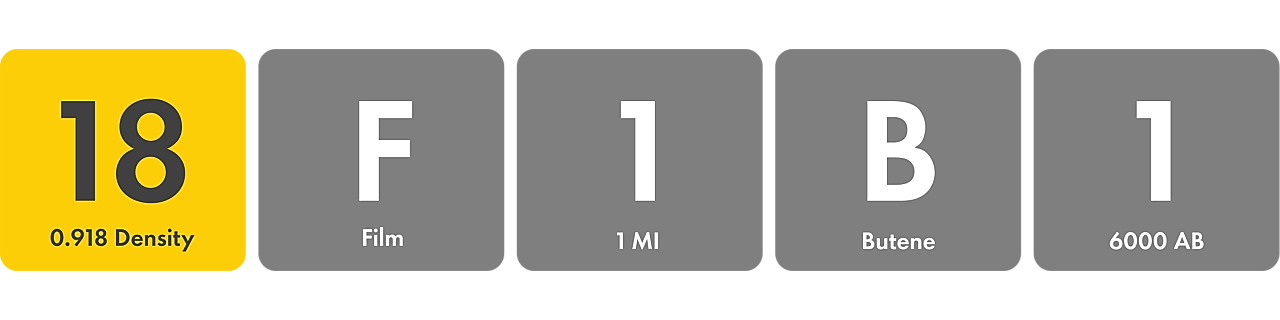

| Shell Polymers LLDPE 18F1B | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F1B1 | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F1B2 | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F2B | 2.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 19F3B | 2.7 | 0.919 | View technical properties |

View injection molding product details

View injection molding product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers HDPE 48N5 | 5.0 | 0.948 | View technical properties |

| Shell Polymers HDPE 52N7 | 6.5 | 0.952 | View technical properties |

| Shell Polymers HDPE 52N10 | 10.0 | 0.952 | View technical properties |

| Shell Polymers HDPE 54N20 | 20.0 | 0.954 | View technical properties |

| Shell Polymers HDPE 65N8 | 8.2 | 0.965 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers HDPE | View document |

| Shell Polymers LLDPE | View document |

| Shell Polymers Polyethylene Wide Spec or Offspec | View document |

Product 101

By understanding our naming system, you can identify the best fit for your agricultural applications, whether you’re manufacturing nursery pots, farm plastic components or long-lasting LLDPE plastic films. This clarity helps ensure you're choosing resins that support both high-efficiency farming and resource use long term.

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Related conversion processes

A few conversion processes can be used to make material such as HDPE corrugated pipe and LLDPE films that are both widely used to power plasticulture.

Film extrusion

Film extruded LLDPE is used to make industrial and food packaging, stretch films and more.

Injection molding

Injection molded LLDPE and HDPE is used to make caps, bottle closures, toys and more.

Stay informed with Shell Polymers

Our monthly newsletter keeps plastic converters like you up to date on the latest in agricultural plastics, from emerging industry trends and resin insights to plasticulture innovations, LLDPE film applications and strategies to help reduce plastic pollution. Get expert tips on materials on farm plastic solutions—delivered straight to your inbox.

Expert insights on plasticulture

The power of multi-layer blown film technology

Is upgrading to a multilayer blown-film line really worth it? Despite the upfront cost, multi-layer machines offer faster output, higher quality and more.

Injection molding troubleshooting: Four common challenges and how to address them

Find out how to solve four common defects that occur during the injection molding production process.

How to enhance your plastic injection molding operation in 3 steps

Learn how your choice of lubricant can impact production, equipment availability, and downtime.

Film extrusion troubleshooting: reduce line downtime with expert tips on lubricants

Our colleagues at Shell Lubricants put together expert tips to help film extruders keep their lines running at peak performance.