Enhance Longevity and Safety With HDPE’s Chemical Resistance

HDPE is a versatile material, most well known for its resistance to outside chemicals and solvents.

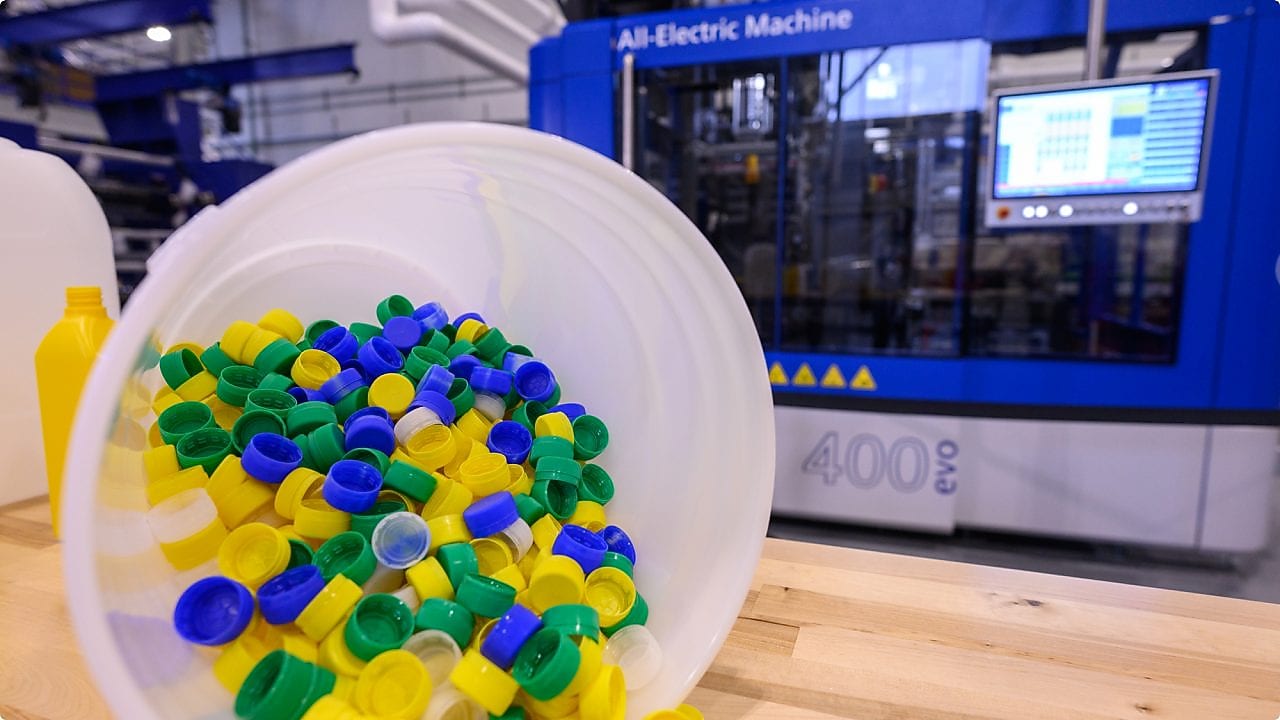

High-density polyethylene (HDPE) can be used to create building materials, plastic film-based garbage bags, and sanitary surfaces. One of its most praised characteristics is HDPE’s chemical resistance. This not only makes it ideal for protective film packaging applications, but also toy parts, buckets, and rigid pipes. HDPE can enhance longevity and safety across a variety of industries including construction, personal care, and education. Here are just a few examples.

1. Increase Construction & Infrastructure Longevity

HDPE is commonly used in construction projects and infrastructure installation as a way to reduce repairs and promote material longevity. Those benefits are helping drive the popularity of HDPE by providing quality materials that resist environmental stress. The HDPE pipe market continues to show a healthy amount of growth as the material becomes more popular among construction companies.1 By leveraging HDPE, construction organizations can reduce the frequency of required maintenance, saving time and money.

The Advantages HDPE in Construction Use Cases

Plastic is one of the most cost-efficient construction materials. In fact, 20% of all plastic produced is used in construction – the second largest application for this material.2 HDPE pipes are corrosion-resistant and recyclable, so they’re seen as an effective replacement to metal pipes. HDPE pipes are also leak-free, lightweight, require less energy to make, and are preferred over traditional metal pipes, which are heavy and are more prone to cracking.

According to the Plastic Pipe Institute., “Polyethylene (PE) pipe's unique characteristics have made it the product of choice for numerous applications in the mining industry. It is a proven product in rugged terrains, extreme climates, and changing site environments. Heat-fused joints create a monolithic structure that allows long lengths of pipe to be pulled from one area to another. PE pipe's flexibility, abrasion resistance and leak-free joints have helped the product prove itself long-term in demanding environments.”3

Project cost creep is a common issue in construction. This is due to unforeseen expenses caused by materials breaking or warping during installation. HDPE’s long service life helps to mitigate those issues and its lightweight nature makes it easier to install than other materials.

HDPE’s Chemical Resistance In Construction

HDPE is resistant to strong acids and bases, reducing agents, and gentle oxidants, which makes it ideal for construction environments where materials may come into contact with such chemicals. Alternative materials like aluminum or steel may interact with certain on-site chemicals, causing weaknesses and breakages down the road that HDPE can help avoid.

2. Chemical Resistance In Home and Personal Care Products

According to Forbes, the packaging industry for consumer product goods, which includes personal care and beauty products, generates more than $25 billion in sales worldwide each year.4 Due to its chemical resistance, HDPE makes an excellent plastic packaging choice for cosmetics. HDPE is also preferred for personal care products because it has high rigidity, long shelf life, and reliable barrier properties.5

Save on HDPE with Injection Molding Simulation

Reduce wasted HDPE and improve product quality and design with injection molding simulation. Get our breakdown to learn how to incorporate simulation into your design process.

Longevity for Personal Care Products

The chemical resistance HDPE offers is especially beneficial when it comes to increasing the longevity of home and personal care products. The application is commonly used in products such as shampoo, conditioner, lotion, and body wash.

For example, a cosmetics package manufacturer recently released a cosmetic tube that protects sensitive products such as natural skincare serums and creams from any harmful elements, preventing cosmetic products from excessive exposure to moisture present in the air. This way, the tube increases the shelf life of cosmetics by 60%.6

Learn more about The Role of Polyethylene Packaging in Consumer Health and Hygiene

Promoting Safety With Household Cleaning

HDPE withstands exposure to chemicals without corroding, making it ideal to household chemicals, such as:

- laundry detergent

- bleach

- antifreeze

- gasoline

In addition, its effectiveness can be strengthened once colored or pigmented. HDPE bottles also promote household container safety by preventing leaks and withstanding temperatures of up to 248 degrees Fahrenheit for a short time or 230 degrees for longer periods.7

3. Promote Safety in Education Spaces

HDPE offers schools a material that can create long-lasting and sanitary surfaces. As enforcing hygiene standards at school increases in importance, efficiency and ease of cleaning is critical for custodial staff. Solid plastic lockers made from HDPE are virtually impermeable to moisture, mold, mildew, rust, and odors, lasting for years without showing age. HDPE lockers are also bacteria-resistant and can be power washed or steam cleaned8 to keep them from showing wear-and-tear too quickly.

HDPE makes durable, affordable chairs and other furniture that is built without crevices for contaminants to collect9 and is resistant to consistent exposure to cleaning solutions, water, acids, and other chemicals. This allows school staff to keep surfaces reliably clean, reducing the risk of spreading infection.

No matter the industry, HDPE will continue to create products with reliable resistance to harmful chemicals and contaminants that hold up over the long term and promote safety.

Learn how Shell’s Polymer Experts Support Customers with Industry Expertise

1 HDPE Pipes Market by Type: Global Opportunity Analysis and Industry Forecast, 2023-2032

2https://www.modernbuildingalliance.eu/environmental-sustainability-plastics-construction/

3 https://plasticpipe.org/municipal_pipe/mid-mining.html

4https://www.forbes.com/sites/kaleighmoore/2019/06/11/new-ways-the-beauty-industry-is-testing--sustainable-practices/#36092b69eb55

5https://www.beroeinc.com/article/pet-hdpe-cost-savings/

6https://www.cosmetic-tubes.com/

7https://www.calpaclab.com/hdpe/

8https://continuingeducation.bnpmedia.com/courses/scranton-products/school-hallway-lockers-made-of-highdensity-polyethylene-hdpe/2/

9https://www.norix.com/durable-furniture-5-advantages-of-polyethylene-furniture-in-your-intensive-use-environment/