How Shell Polymers Plans to Reshape the US Polymers Market

As one of the most popular chemical compounds in the world, future applications of polyethylene are endless. That’s why the North American PE industry continues to grow and producers are evolving to keep up with need.

That said, as demand rises, sustainability must be an essential part of new plastics development. These changes are one reason Shell recently announced it has successfully made chemicals using a liquid feedstock made from plastic waste. The technique, known as pyrolysis, is considered a breakthrough for hard-to-recycle plastics and advances Shell’s ambition to use one million tonnes of plastic waste a year in its global chemicals plants by 2025.

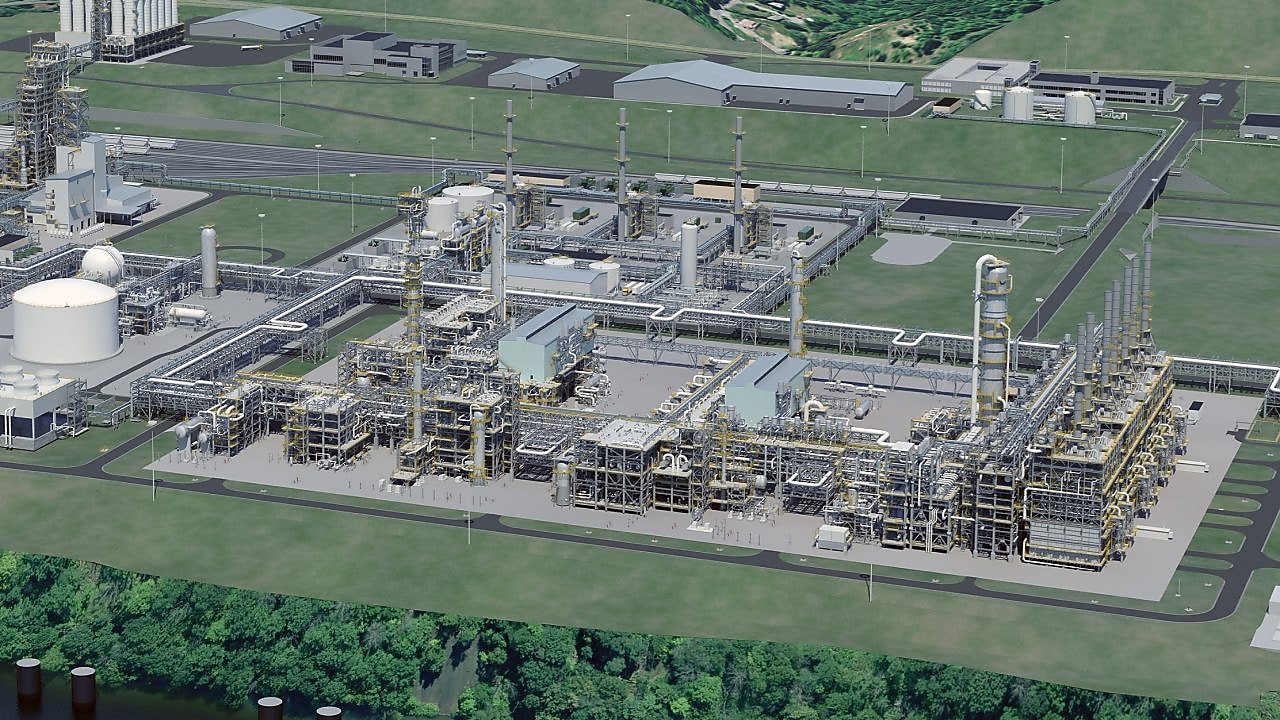

As we complete our new petrochemicals plant in Pennsylvania and continue exploring technology like this, we’re prepared to reshape the U.S. polymers industry and capitalize on the industry’s massive growth. To do that, Shell Polymers is building state-of-the-art facilities, unrivaled customer service, and a diverse team of polymer pioneers and pros.

At Shell Polymers, we break the mold by providing a top-notch customer experience, tailored to the needs of each customer. Our facilities will be equipped with the technology to create high-quality products and staffed with knowledgeable industry pioneers eager to lend their expertise and support your business.

Explore A Map Of Our Pennsylvania Polyethylene Plant

Unrivaled Customer Experience

We’re implementing business tools and procedures that are specifically designed for a PE converter’s distinct needs, so management tasks can get done efficiently. If an issue occurs, we’ll take the initiative to reach out proactively, so our customers can have peace of mind that urgent updates will be communicated in a timely manner.

In addition to customer-centric communication that always keeps you in the loop, we are building an 85,000 square-foot application hall on site that is stocked with cutting-edge analytical resources and full-scale conversion equipment, so we can deliver an unrivaled customer experience in all areas.

Polymer Pro Innovators

That said, the technology within the application hall is just one piece of the puzzle. We've also gathered the industry experts to help converters troubleshoot and trial solutions right in their backyard. Collectively our polymer experts have over 750 years of experience and are committed to delivering an unrivaled customer experience by putting your unique needs first.

Experts at the Ready

Read the transcript

Read the transcript

Title: Dan Moldovan

Duration: 33 seconds

Description:

A short video of Dan Moldovan speaking about Shell Polymers.

Dan Moldovan Transcript

[Dan Moldovan, speaking to camera]

We have the opportunity as a new company coming into this industry to develop a new culture dealing with our customers to create a new experience for our customers and develop new products and new ways to do things from a polyethylene standpoint. So, nobody in the past has done that, so it’s great opportunity for us and our customers. At Shell Polymers, we are making the experience matter.

Senior Technical Service Engineer and Shell Pioneer, Dan Falla, is an excellent example of Shell Polymers’ commitment to meeting customer needs with high-quality collaboration. When an equipment manufacturer was looking for a resin that could process 3% faster, Dan was up for the challenge. He went back to the laboratory and launched an R&D program that identified a minor resin modification that could increase a polymer’s output rate by not just 3%, but 20%!

Discover More Polymer Experts In A Fireside Chat with Polymer Pioneers: Pipe & Film

State-of-the-Art Facilities

We want converters to have every opportunity to improve product quality, consistency, and output. That’s why we’ve integrated smart inspection technology such as drones, crawlers, and connected equipment into our daily operations. As we build from the ground up, we’re able to leverage all of Shell's expertise and experience constructing large scale assets around the world.

These advancements reflect some of the core ways our Monaca polyethylene plant will help us reshape the polymers industry. Stay up-to-date on our progress and sign up for plant updates below.

The expression ‘Shell’ or ‘Shell Polymers’ refers to the companies of the Shell Group that are engaged in chemical businesses. Each of the companies that make up the Shell Group of companies is an independent entity and has its own separate identity.

Disruptions Hurt Converter Profits

Minimizing delays will maximize profits. Learn how that can happen with consistent customer support, friction-free tools, and more.