How Shell Polymers Challenges the Status Quo with Logistics Technology

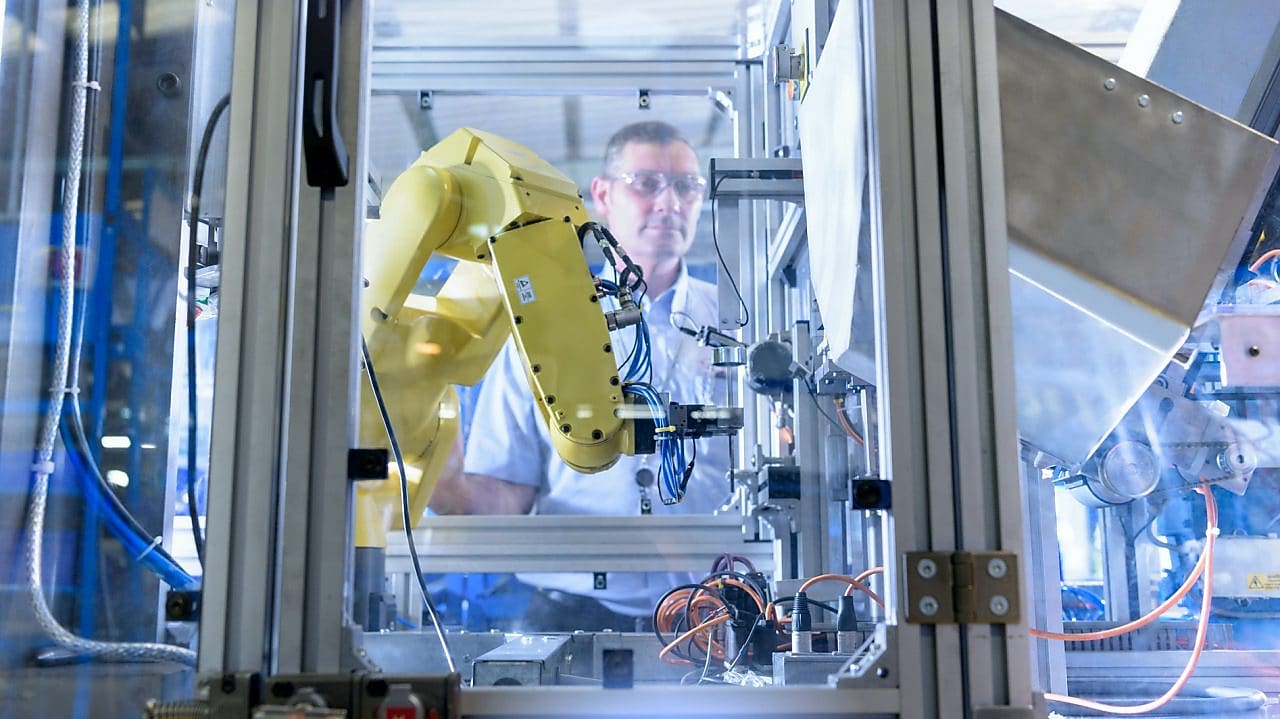

Shell Polymers’ plant will feature state-of-the-art logistics technology that will allow us to work hand-in-hand with our customers.

From arbitrary ETAs to long-winded customer experiences, logistics have been a cause of frustration for companies that rely on supply chains to keep their business processes flowing.

As part of our efforts to reimagine the customer experience, Shell Polymers strategically placed our plant’s location in the northeast, implemented technology, and brought on a passionate team of logistics pros.

Accessible Location & Supply Chain Flexibility

Accessibility to a consistent supply is essential for plastic converters. That’s why Shell Polymers’ new plant is in the northeast, right in the customer’s backyard. The plant’s location in Monaca, Pennsylvania puts us within 700 miles of the majority of current polyethylene buyers.

This allows us to meet customer needs quicker and more efficiently with greater supply chain flexibility. In addition to streamlining product deliveries, our logistics processes optimize trucking to make it a more viable option when needed.

Trucking offers a variety of benefits, such as higher reliability, quicker delivery, and less capital tie-up, as well as being ideal for transporting small loads. Shell Polymers implemented large-capacity truck silos on-site, which allows us to top-load trailers for deliveries. This leads to shorter lead times and higher-quality products as they reduce opportunities for potential contaminations. Additionally, truck deliveries could allow customers to reduce working capital as their inventory spends less time tied-up in moving rail cars.

Trucking can offer a variety of benefits, such as higher reliability, quicker delivery, and less capital tie-up, as well as being ideal for transporting smaller resin shipments.

Shell Polymers has invested in silo-top truck loading at the plant. This fast and efficient infrastructure can load a truck in just 20 minutes, lessens converters’ dependency on railcars, and also helps remove “angel hairs,” leading to a higher-quality product.

For other customers, shipments by rail will be the preferable option.

Learn More About Shell Polymer’s Accessible Pennsylvania Polyethylene Plant

The Future of Logistics Technology

While trucking has potential in the near-term, other technologies are coming around the corner that will revolutionize logistics processes. Specifically, advancements in GPS capabilities bring transparency to production processes and help companies proactively prevent logistical kinks from interfering with customer deliveries and ensure smooth operations.

At Shell Polymers, all logistic capabilities are being built so we can easily upgrade and adopt next-generation technology when it becomes available. We’re employing new kinds of always-on tools and support to offer a seamless transportation experience for our customers. That includes making all of our hopper cars GPS-ready so customers can easily track their shipments via our Customer Hub like they would with any retail shipment.

At Shell Polymers, all logistic capabilities are being built so we can easily upgrade and adopt next-generation technology when it becomes available.

Advanced logistics tools will also include a robust notification system that proactively keeps our customers up-to-date on the status of their orders, reducing last-minute surprises and providing transparency into our operations. When paired with our knowledgeable team of polymer experts, our logistics technology helps our customers prevent costly operational hiccups and increase supply chain efficiency and reliability.

Discover Why Converters Should Diversify Their Supplier Pool with Shell Polymers

Shell Polymer’s Logistics Experience

With over 750+ years of collective experience in the polyethylene industry, Shell Polymers’ industry pioneers are committed to breaking the polyethylene provider mold. At Shell Polymers, the technology is just one part of the equation. Backed by our extensive logistics experience across Shell, Shell Polymers employs experienced logistics experts to develop and implement technology in our plant, allowing us to provide you with better customer care and polymer supply chain flexibility.

At Shell Polymers, our team of passionate professionals is leveraging advanced logistics technology to ensure success by offering a variety of reliable logistics options, such as proactive notifications and leveraging analytics, to serve our customers better.

Trending Articles

By Shell Polymers on May 21, 2020

By Shell Polymers on Jul 08, 2020

By Shell Polymers on Jul 16, 2020

Get Ahead of Industry 4.0 Shifts Changing the Polymers Industry

Discover insights on Industry 4.0 technology to stay updated on the new era of manufacturing.