Film extrusion

At Shell Polymers, we understand that a converter’s business runs entirely on resin—which is why we’re committed to helping converters find the right resin that fits your needs. That’s why our polymers undergo rigorous testing for tensile strength, impact resistance, tear strength and more. Each formulation is built to deliver consistent performance in polyethylene film applications. The end result? A quality and reliable supply that meets the demands of modern polyethylene film production.

Expert insights on film extrusion & market trends

The power of multi-layer blown film technology

Is upgrading to a multilayer blown-film line really worth it? Despite the upfront cost, multilayer machines offer faster output, higher quality and more.

Coextrusion & the future of blown film

Learn about the benefits of coextrusion, from improved product performance to reduced costs and a more sustainable packaging solution.

The latest innovations in blown film production

Our film extrusion trends overview gives you a quick rundown of what blown film converters need to know—from new technologies and techniques to the continued rise of flexible packaging.

Ensure a trouble-free film extrusion machine shutdown

Learn how a proper shutdown procedure can help maximize your productivity and margins.

Product summary

View LLDPE product details

View LLDPE product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers LLDPE 18F1B | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F1B1 | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F1B2 | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F2B | 2.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 19F3B | 2.7 | 0.919 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers LLDPE | View document |

| Shell Polymers Polyethylene Wide Spec or Offspec | View document |

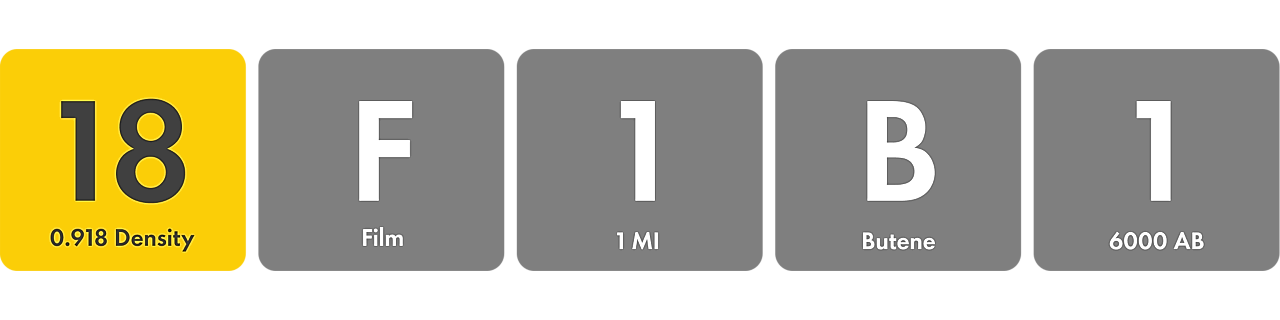

Product 101

At Shell Polymers, our polyethylene resins help protect quality and optimize production across various types of packaging and types of food packaging materials. Explore the technical details below to compare melt index, density and documentation for each of our food-grade options.

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Our film extrusion expertise

Shaun Pirtle, Senior Technical Service Engineer & Competency Advisor

Shaun has 34+ years’ experience in polyolefins manufacturing, customer support and product innovation.

“We are committed to providing best-in-class service and products. That means not only listening to the customer but also responding appropriately and in a timely fashion.”

Brennan Wodrig, Technical Service Engineer

Brennan brings over a decade of experience in polymers processing. A graduate of Pennsylvania College of Technology in Plastics and Polymer Engineering Technology, he has contributed to workforce training and process innovation at the college's Plastics Innovation and Resource Center.

Stay informed with Shell Polymers

Our monthly newsletter keeps plastic converters like you up to date with the latest on food packaging materials, industry trends, and technical tips from our experts—delivered straight to your inbox.

Have questions about food packaging materials? Let’s connect

Film extrusion in action across markets

Polyethylene film is a versatile material produced through the film extrusion process and used across a wide range of markets—from healthcare and industrial to flexible packaging, blown film and other plastic film applications. Whether you're developing extruded products for protective packaging, hygiene films, or heavy-duty liners, selecting the right resin is essential for consistent performance and efficiency throughout your extrusion process.

Agriculture

HDPE and LLDPE are used to create containers that can safely store agricultural products.

Household

Durable and leak-resistant containers for household chemicals can be made with HDPE or LLDPE.

Food packaging

Polymer packaging made with LLDPE or HDPE helps protect food from delivery and shipping to your kitchen.

Industrial

Manufacturing products such as crates, blown film and drums benefit from HDPE or LLDPE, depending on the use case.

Healthcare

Depending on the product’s desired properties, HDPE and LLDPE are used to make industrial packaging and blown film.

Case studies

Identifying the cause of quality issues in film extrusion

Our case scenario demonstrates how our processes and insights ensure your resin is properly handled throughout transit—including when it arrives at your site.

Entering new markets in film extrusion

In this sample scenario, we demonstrate how Shell Polymers can help develop a new product to capture additional market share without any downtime for your facilities.

Improving profitability in film extrusion

Check out our expert tips on how new technology can make the most of your film extrusion line to unlock advantages for your business.