Pipe extrusion

Plastic converters producing underground pipe need plastic materials that meet strict HDPE pipe requirements and are resistant to chemicals, solvents and environmental stressors. At Shell Polymers, we understand choosing the right raw material is essential for consistent, high-performance results in the pipe extrusion process. That’s why we deliver HDPE resins that undergo rigorous testing to help meet the technical demands of plastic pipe extrusion. Whether you're operating a pipe extrusion line for infrastructure or industrial applications, our resins are engineered to support the production of durable, reliable extruded pipe.

Expert insights on pipe extrusion & market trends

Breaking down salt and pepper mixing vs. precompounded

In some regions, resins are precompounded; in others, converters feed resin to the extruder with masterbatch. Some claim this “salt and pepper” mixing results in inferior quality—but is that actually true?

Pipe extruders should look at HDPE as the future of utilities infrastructure

Learn the benefits of using HDPE for underground pipe systems, from strength and durability to abrasion resistance and more.

Five things you need to know about HDPE pipe

HDPE pipe is a rapidly growing industry that’s attracting new investment. Learn why HDPE pipe is so useful and how working with the right polymer supplier can help you make the most of new opportunities.

Product summary

View HDPE product details

View HDPE product details

| Product | Melt index | Density | Product details |

|---|---|---|---|

| Shell Polymers HDPE 48P9HL | 9.0 HL | 0.948 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers HDPE | View document |

| Shell Polymers Polyethylene Wide Spec or Offspec | View document |

Product 101

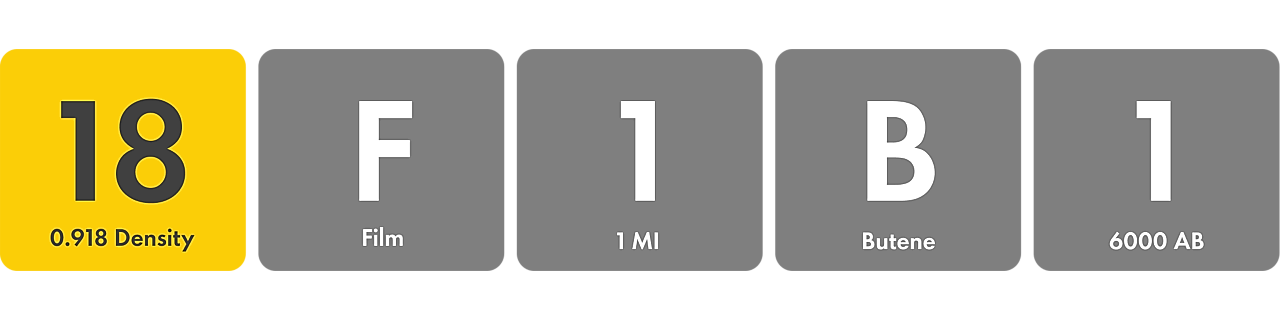

We’re here to help you quickly identify the raw material that matches your plastic processing requirements—that’s why understanding our naming convention is key to selecting the right melt index and density for your pipe extrusion process. Whether you're producing extruded pipe, managing a full pipe extrusion line, or running an HDPE extrusion operation, we understand the importance of choosing materials that help support consistent, high quality pipe production.

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Our pipe extrusion expertise

Carl Baker, Senior Technical Service Engineer

With more than 35 years of experience in extrusion pipe and helping customers innovate, Carl holds leadership positions in several key industry organizations such as the Plastic Pipe and Fittings Association.

“The equipment in our application hall enables us to unlock technical insights for customers. For example, if they’re having a product issue we can run their current formulation on our machines to investigate solutions. By running those trials here, they don’t have to stop their production, and that’s really significant because most pipe extruders run 24/7/365. Stoppages mean lost production and can lead to start-up difficulties.”

Stay informed with Shell Polymers

Our monthly newsletter keeps you up to date on pipe extrusion process trends and plastic processing tips as well as insights on raw material, pipe cooling and achieving high quality results on your pipe extrusion line.

Pipe extrusion in action

Pipe extrusion plays a critical role in markets like Utilities, where long-lasting HDPE pipes provide the strength, corrosion resistance, and leak resistance needed for high-performance infrastructure applications. By choosing the right plastic material and optimizing the pipe extrusion process, manufacturers can deliver durable solutions that meet evolving market standards.

Utility infrastructure

HDPE is one of the most popular pipe materials for utilities because of its strength and resilience.