Outdoor Living

From playground equipment to greenhouses to the classic Adirondack chair, linear low density polyethylene (LLDPE) and high density polyethylene (HDPE) have become the go-to material for products in outdoor spaces due to their moisture and temperature resistance. At Shell Polymers, our team helps ensure materials are optimized for real-world use thanks to in-depth testing at our Innovation Center and a focus on responsive customer service.

2025 industry trends shaping the future of outdoor living

The plastics industry is competitive and keeping pace with packaging industry trends is crucial for growth. In our Shell Polymers 2025 Trend Report, we’ll explore trends, threats and opportunities for converters—including a look at shifts that affect the high density polyethylene outdoor furniture market.

Product summary

View blow molding product details

View blow molding product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers HDPE 46BG6HLU | 6.0 HL | 0.946 | View technical properties |

| Shell Polymers HDPE 48BG9HL | 9.0 HL | 0.948 | View technical properties |

| Shell Polymers HDPE 55B035 | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 55B035A | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 63B072 | 0.72 | 0.963 | View technical properties |

View rotomolding product details

View rotomolding product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers LLDPE 35R5U | 5.2 | 0.935 | View technical properties |

| Shell Polymers LLDPE 35R7U | 7.0 | 0.935 | View technical properties |

| Shell Polymers LLDPE 39R4U | 3.5 | 0.939 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers HDPE | View technical properties |

| Shell Polymers LLDPE | View technical properties |

| Shell Polymers Polyethylene Wide Spec or Offspec | View technical properties |

Product 101

No matter what you’re manufacturing, our linear low polyethylene and high density polyethylene offer the durability, weather resistance and long-term value you need for demanding outdoor spaces. Explore the technical details below to compare melt index, density and technical documentation for each of our options.

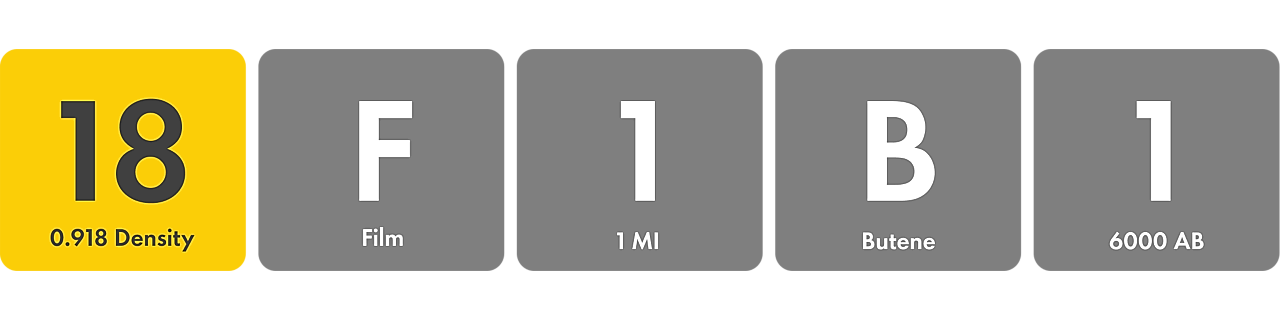

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Related conversion processes

Different conversion processes can take the same polymers and transform them into a wide variety of plastic products—from an Adirondack chair to a patio set or recreational structure.

Blow molding

Blow molded HDPE is used to make hollow products such as industrial containers and drums, liquid containers and more.

Rotomolding

Rotomolded LLDPE is used to make large products such as playgrounds, industrial containers and more.

Stay informed with Shell Polymers

Our monthly newsletter keeps plastic converters like you up to date with the latest on outdoor living materials, industry trends, and technical tips from our experts—delivered straight to your inbox.

Have questions about outdoor living materials? Let’s connect

Expert insights on outdoor living market

How to prepare for LLDPE rotational molding operations

Learn three best practices when it comes to LLDPE rotomolding.

High-quality resin can increase blow molding machine production

Improving production is always a top priority for converters and resin plays an important role in this. Learn how suppliers can help ensure resin meets a converter’s quality needs.

Rotational molding troubleshooting: 4 tips to prevent defects

Minimize expensive rotomolding defects with these expert insights.