Household

In the consumer goods and household products space, durable and well-designed packaging plays a vital role in protecting families and extending shelf life. At Shell Polymers, we deliver solutions that help support sustainable packaging goals and maintain the quality standards expected in the consumer packaging and food and beverage industries across a wide range of consumer products.

2025 industry trends shaping the future of consumer goods

The plastics industry is competitive and keeping pace with packaging industry trends is crucial for growth. In our Shell Polymers 2025 Trend Report, we’ll explore trends, threats and opportunities for converters, including a look at shifts that affect the household market.

Product summary

View blow molding product details

View blow molding product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers HDPE 46BG6HLU | 6.0 HL | 0.946 | View technical properties |

| Shell Polymers HDPE 48BG9HL | 9.0 HL | 0.948 | View technical properties |

| Shell Polymers HDPE 55B035 | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 55B035A | 0.35 | 0.955 | View technical properties |

| Shell Polymers HDPE 63B072 | 0.72 | 0.963 | View technical properties |

View film extrusion product details

View film extrusion product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers LLDPE 18F1B | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F1B1 | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F1B2 | 1.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 18F2B | 2.0 | 0.918 | View technical properties |

| Shell Polymers LLDPE 19F3B | 2.7 | 0.919 | View technical properties |

View injection molding product details

View injection molding product details

| Product | Melt index |

Density |

Product details |

|---|---|---|---|

| Shell Polymers HDPE 48N5 | 5.0 | 0.948 | View technical properties |

| Shell Polymers HDPE 52N7 | 6.5 | 0.952 | View technical properties |

| Shell Polymers HDPE 52N10 | 10.0 | 0.952 | View technical properties |

| Shell Polymers HDPE 54N20 | 20.0 | 0.954 | View technical properties |

| Shell Polymers HDPE 65N8 | 8.2 | 0.965 | View technical properties |

View safety data sheets

View safety data sheets

| Document title | Document |

|---|---|

| Shell Polymers HDPE | View technical properties |

| Shell Polymers LLDPE | View technical properties |

| Shell Polymers Polyethylene Wide Spec or Offspec | View technical properties |

Product 101

At Shell Polymers, our polyethylene resins help support efficient production across a wide range of consumer packaging and food and beverage applications. From rigid containers to flexible films, our materials are engineered to enhance product packaging performance, extend shelf life and support packaging design goals. Explore our technical details to compare technical details for each of our consumer goods packaging materials.

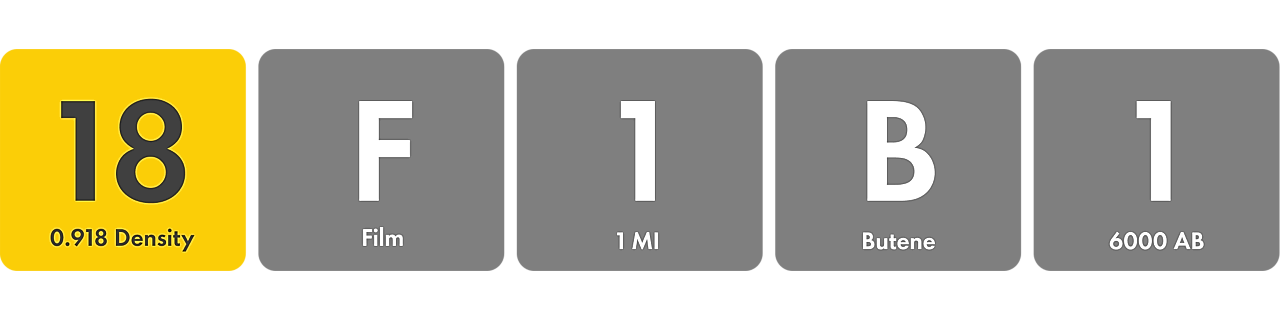

Density is reflected by the first two numbers found in the product name, which is 18 in this instance. These numbers represent the last two significant digits of the density value. See examples below.

18 = 0.918 density

53 = 0.953 density

63 = 0.963 density

Related conversion processes

A few conversion processes can be used to make items such as leak-resistant consumer goods packaging containers that keep your family safe from chemicals.

Blow molding

Blow molded HDPE is used to make hollow products such as industrial containers and drums, liquid containers and more.

Film extrusion

Film extruded LLDPE is used to make industrial and food packaging, stretch films and more.

Injection molding

Injection molded LLDPE and HDPE is used to make caps, bottle closures, toys and more.

Stay informed with Shell Polymers

Learn how recycled materials and innovative packaging materials are shaping the future of consumer goods with our monthly newsletter—delivered straight to your inbox.

Have questions about consumer goods packaging? Let’s connect

Expert insights on consumer goods packaging

The power of multi-layer blown film technology

Is upgrading to a multilayer blown-film line really worth it? Despite the upfront cost, multi-layer machines offer faster output, higher quality and more.

Coextrusion & the future of blown film

Learn about the benefits of coextrusion, from improved product performance to reduced costs and a more sustainable packaging solution.

High-quality resin can increase blow molding machine production

Improving production is always a top priority for converters and resin plays an important role in this. Learn how suppliers can help ensure resin meets a converter’s quality needs.

Injection molding troubleshooting: Four common challenges and how to address them

Find out how to solve four common defects that occur during the injection molding production process.