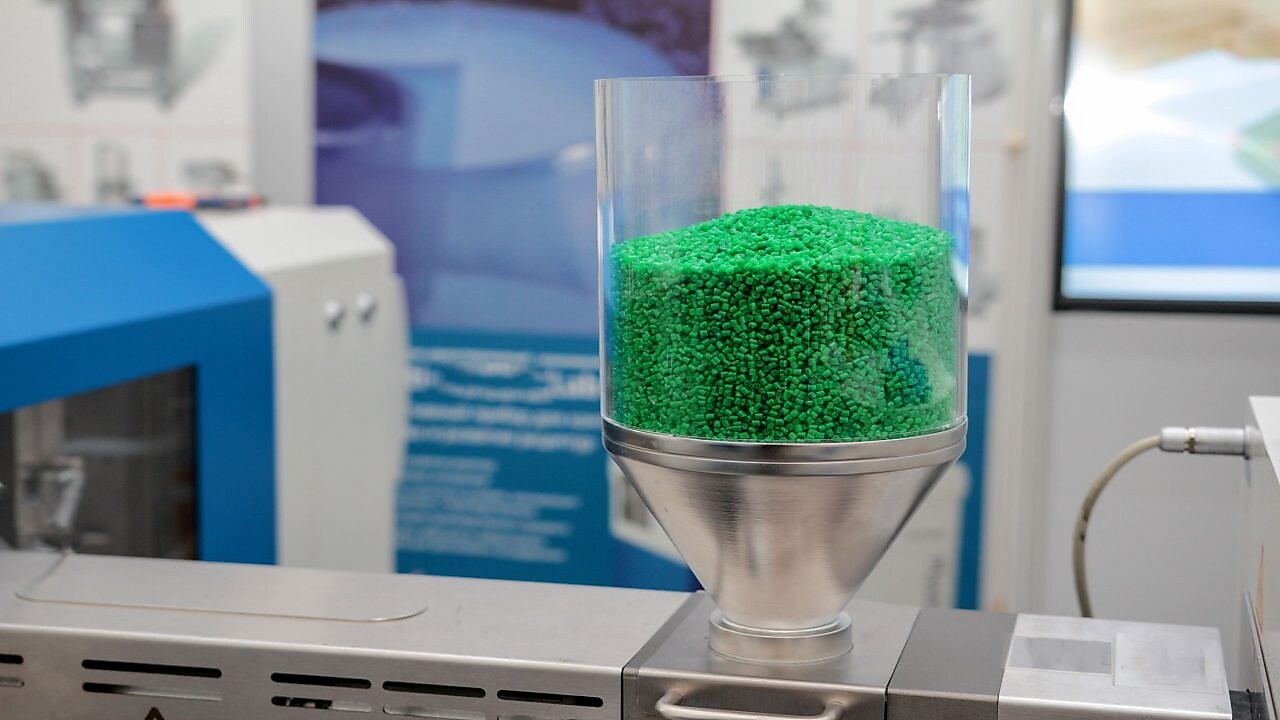

Lubricants for Plastic Injection Molding

Hydraulic fluid is the lifeblood of a hydraulic injection molding machine. Investing in a high-quality hydraulic fluid may be seen by some as a non-essential expense. The reality is, high-performance lubrication can deliver significant long-term savings and improve your total cost of ownership.

Case studies & resources

Explore lubricants for your business

No Time for Downtime?

Download the guide to learn more about the four surefire ways to ensure your plastics injection operation runs like a well-oiled machine.

Read Guide

Stay Connected with Shell

Sign up to receive the latest insights, trends, and best practices for lubricants in plastic injection molding.

Sign-Up